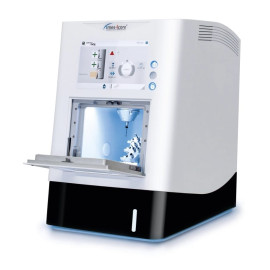

VHF S1 5-axis dry and wet dental milling machine

Your shopping cart is empty!

Product Description

Condition: Brand New

Warranty: 2 Years Global Warranty

Payment method: Crypto Currency,Bank to Bank Transfer,Western Union,Ria Transfer,Money Gram,e.t.c

Delivery method: 4 to 5 working days (door to door delivery).

Specification:

Fileds of application dry and wet machining

Machinable materials plastics,wax,zirconium oxide,composites,CoCr,glass ceramics

Indications crowns,bridges,fully anatomical crowns and bridges,inlays,onlays,abutments,telescope crowns,models plates,model

casts bite splints,model plug-in teeth,implants bars,veneers,table-tops

Basic systems

Construction machine bed of massive aluminium cast

No. of axes 5

x/y/z pos.range 140 x 98 x 76 mm

Drives precise ball screw spindles for the 3 linear axes

motor resolution< 1 um

ground steel precision guide rails

4 mm spindle lead angle

Repetition accuracy + or - 0.003 mm

Axis measurement measurement of axes with callibration specimen

automatic axis compensation for exact rssults

Housing Complete encapsulation of working chamber with closable front cover

automatic safety interlock at the front cover during the machining process

Working chamber illumination yes

Dimension(W/D/H) approx. 490 x 445 x 540 mm

Weight approx. 75 Kg

Rotary axes

Feature A axis: highest true running accuracy for processing work-pieces on their full circumference of 360 degree.Harmonic Drive

free from backlash

B axis: highest true running accuracy.rotation range of up to + or - 30 degree.Harmonic drive free from backlash

Fixing device round universal blanks with a thickness of 10 to 30 mm and a diamter of 98.5 mm with step; for wet grinding option:three

fold block holders

Exchange of workpieces manual exchange of blanks

Controller

Features type CNC G12D

synchronic interpolation of 5 axes

great smoothness of running,powerful and accurate due to microstep operation

high processing speed due to exponential acceleration acceleration ramps

look-ahead feature for continuous velocity along the path

8 digital inputs,8 digital outputs

5 motor end phases

four quadrant controller

no fan necessary for cooling

optional ethernet interface

Spindle

Features synchronous spindle SFS 300P

normal power under constant load(S1): 300 Watt

maximum power output (Pmax): 600 W

rotational speed range up to 60,000 RPM

4-fold hybrid ceramic ball bearing

radial deviation at internal cone of the precision shaft < 1 um

sealing air prevents entering of foreign substances in the bearing area

cone cleaning

Collect chuck pneumatic stainless steel collect chuck for tools with 3 mm shank diameter and max. 40 mm total length

Tool Change

Features automatic tool change station for 16 tools

haptic tool length detection and tool breakage monitoring

diamond-coated tools can be used

compessed air monitoring

Wet grinding

Features 3 liquid nozzles at the spindle for wet grinding

external wet grinding module(optional)

Air extraction

Feature opening at the housing side for air extraction

underpresssure sensor for monitoring the air extraction

24 volt output for conncting the switching unit

Other

Peripheral equipment switching unit PSW O1 -RSV for automatically switchinga vacuum cleaner

wet grinding option

administrated tool board

block holder for glass ceramics

blank operation board

bank frame tower

Special feature certification according to ANSI/UL 61010-1 for exports to the USA and Canada